What is Digital Twin?

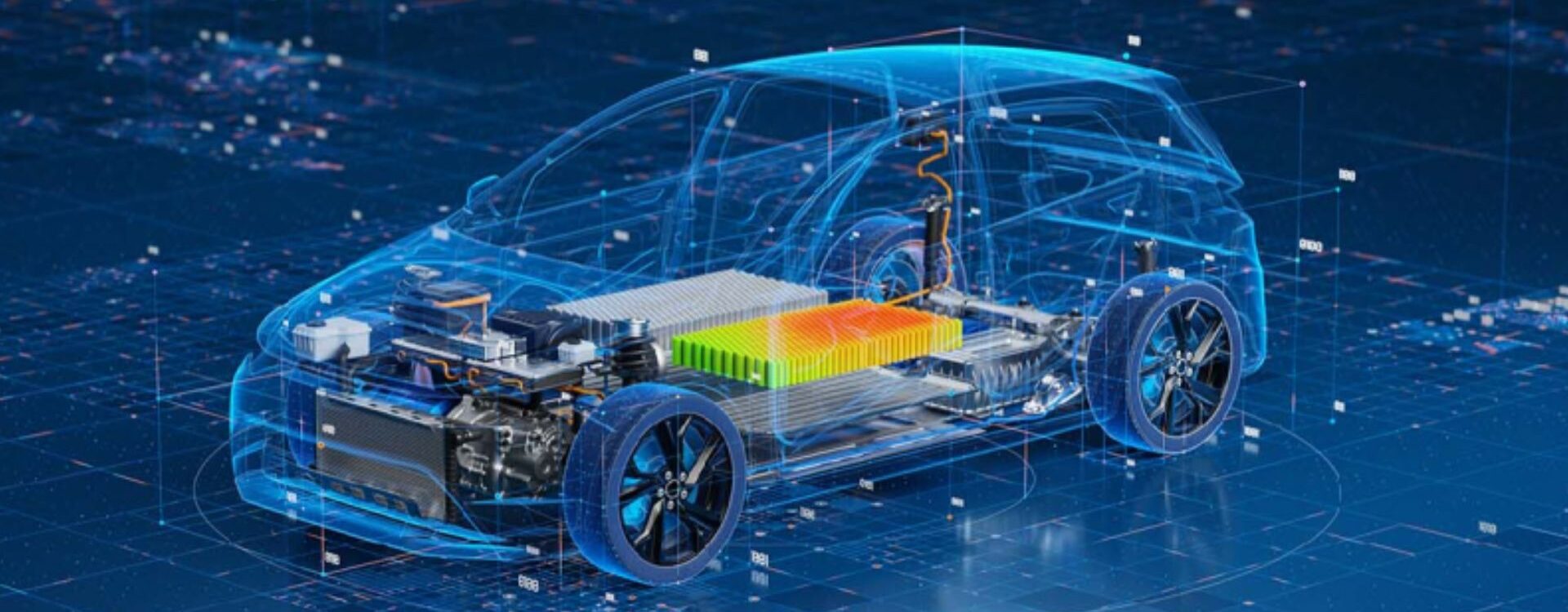

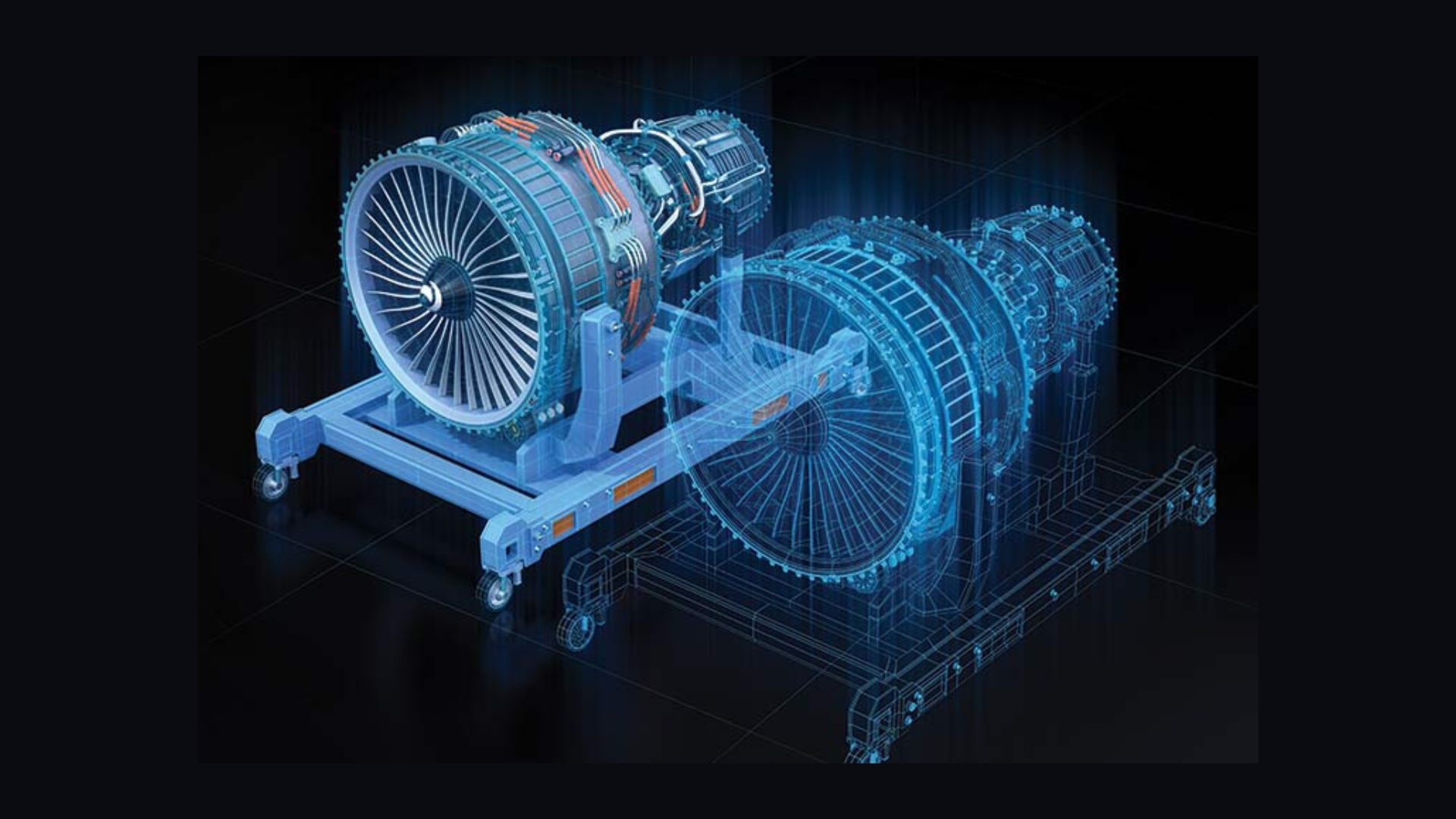

A digital twin is a virtual representation of a physical product, process, person, or place that can understand and measure its physical counterparts.

A digital twin has three components: a digital definition of its counterpart (generated from CAD, PLM, etc.), operational/experiential data of its counterpart (gathered from Internet of Things data, real-world telemetry, and beyond), and an information model (dashboards, HMIs, and more) that correlates and presents the data to drive decision making.

A digital twin is much more than a simulation, which is merely a data-driven prediction for how a physical environment/process/person/product will behave. A digital twin spans the full product lifecycle and has engineering, manufacturing, and service use cases.

Why is Digital Twin important?

With continued advances in digital technology, digital twins are becoming more robust—and more important to enterprise companies. With digital twin technology, companies can use real-world product data to inform improvements to the next generation of product, identify bottlenecks in processes with more ease, or support service technicians in the field leading to faster repair. When looking at use cases for digital twins, consider the ROI and value they will bring to the business.

What are some challenges the Digital Twin helps solve?

🔸 Downtime reduction

Downtime, planned or unplanned, can cost a company significant money. With digital twin technology, businesses can be better prepared to solve issues faster, or avoid them altogether.

🔸 Product improvements

Product designers can use the insights from digital twins to improve the product in future iterations or uncover opportunities for new product lines or features based on product usage data.

🔸 Optimize service capabilities

Support service technicians and customers with guidance via augmented reality to deliver remote expert service or improve first-time fix rates.

🔸 Operational efficiency

Digital twins can expose previously undetectable issues and guide managers to make data-driven improvements.

🔸 Improve customer experience

Digital twins can be used to deliver novel experiences and features to customers.

🔸 Consistent product quality

Because digital twins have a physical counterpart, operators can see detailed data and insights, find patterns, and resolve quality or service issues proactively.

What can Digital Twin do?

Future of Digital Twin technology

New technologies are emerging that will enable high-fidelity digital twins, as well as connections to transformative manufacturing processes, from generative design to additive manufacturing. Digital twins, when combined with artificial intelligence capabilities, such as machine learning and deep learning algorithms, will derive new operational insights. Increased transparency and security will be made possible with blockchain as well.

As digital twins become more prevalent across the industry, there is great potential in orchestrating digital twin networks and enabling communications between two distinct digital twins.